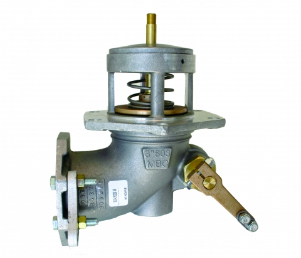

FIG 1218C

Electronic Tank Gauge Wireless Connectivity Accessories

Gauges and Alarms | Electronic Gauging Systems

CARB Installer Certification

We've made CARB Installer Certification quick and simple. You will be provided with the tools needed to complete your certification requirements online. There is no cost to register and complete this exam.

Carb CertificationOur Capabilities

State-of-the-art rapid prototyping, research and development. We specialize in small and medium runs of brass and aluminum alloys with complete in-house CNC machining and finishing capabilities.

CapabilitiesFIG 1218

The Morrison 1218 electronic tank gauge series monitors and displays the liquid level and/or volume of product stored in 1 to 4 aboveground storage tanks. The tank sensor utilizes a mechanical float to monitor the tank liquid level and electronically converts the tank level to display on the system console located within 1000’ of the tank sensor.

System Console Features

Tank Sensor Features

Configuration Options

Network Connectivity

Business Management System Connectivity

Reports

Specifications

Operating temperature Range: -40°F to 140°F (-40°C to 60°C)

Humidity: 0% to 95% non-condensing

System console dimensions (H x W x D): 9⅜” x 7⅞” x 4⅝”

100-240 VAC +/- 10%, 50/60 Hz

Materials of Construction

Approvals

UL/cUL 913; UL/cUL 508; Listing for Tank Monitoring Equipment for Ordinary Location with Hazardous Location Intrinsically Safe Input Circuits for Class I, Division 1, Group D; Florida DEP EQ-872

| Fig | Suffix | Description | Weight |

| 1218C | 0000 AC | Remote secondary console (optional) | 6 |

| 1218C | 0200 AC | System console monitors up to 2 tanks | 6 |

| 1218C | 0400 AC | System console monitors up to 4 tanks | 6 |

| 1218S | 2500 AS | 25’ tank level sensor | 8 |

| 1218S | 2510 AS | 25’ tank level sensor with drop tube float | |

| 1218S | 5000 AS | 50’ tank level sensor | 11 |

| 1218S | 5010 AS | 50’ tank level sensor with drop tube float | |

| 1218S | 2539 CC | 1,000’ spool Belden 7933A cable | |

| 1218S | 2543 CC | 50’ spool Belden 7933A cable | |

| 1218S | 2544 CC | 100’ spool Belden 7933A cable | |

| 1218S | 2545 CC | 500’ spool Belden 7933A cable |