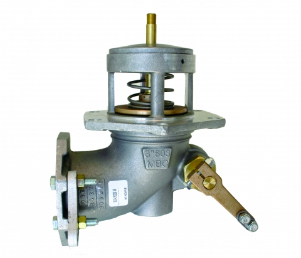

FIG 710SS

Solenoid Valve, SS

Normally closed solenoid valves are used to help prevent the accidental siphoning of a product from a tank in the event of a leak downstream below the liquid level. Generally installed on the dispensing side of a fuel system pipeline. The valve opens upon the receipt of an electronic signal such as when a dispenser or pump is switched to the on position.

NOTE: Product can only be pumped in one direction, the direction of the flow arrow. Not designed for use as an overfill prevention or process control valve.

Product Features

Standard Features

Normally closed, hung piston design

Install in a horizontal pipeline in the upright vertical position

Minimum operating temperature is -40°F

Zero pressure differential

Integral thermal relief allows the valve to relieve expansion pressure in the opposite direction of flow

Continuous duty Class H standard coil operates at 120 volts

Several optional coil voltages available

Enclosure is watertight and rated for hazardous locations—NEMA 3, 4X, 7 and 9; groups C and D

Recommended for use with liquids having a maximum viscosity of 60 centistokes

A strainer with a 100 mesh screen is recommended at the valve inlet

Construction Details

- Body: Stainless steel

- Seals: FKM, PTFE

- Solenoid housed in an integral, watertight, explosion-proof shell

- Piston: Stainless steel (3/4”-2” models) or aluminum (3” models)

Certifications & Listings

CSA listed (File No. 108921, Model Z1314); Class I, Groups C and D; Class II, Groups E, F and G; Class III; T3C; cULus listed

Product Ordering Instructions

| Figure | Suffix | Size | Description | Weight (lbs) |

| 710SS | 2075 1V | .75” | Solenoid Valve, SS (PTFE), w/120/60 Volt AC Coil | 13 |

| 710SS | 2100 1V | 1” | Solenoid Valve, SS (PTFE), w/120/60 Volt AC Coil | 15 |

| 710SS | 2150 1V | 1.5” | Solenoid Valve, SS (PTFE), w/120/60 Volt AC Coil | 16 |

| 710SS | 2200 1V | 2” | Solenoid Valve, SS (PTFE), w/120/60 Volt AC Coil | 21 |

| 710SS | 0300 1V | 3” | Solenoid Valve, SS (Aluminum Piston) (FKM Seal), w/120/60 Volt AC Coil | 44 |